With efficiency in pole position

80 automotive components – and 80 customised load carriers: In an unprecedented project, FEURER is working for a renowned French automobile manufacturer as a full-service provider in the field of load carriers. “Every component of the model is packaged with a custom-fit solution from our company,” explains Markus Feurer, Managing Partner of the FEURER Group. In the factory, the load carriers are an integral part of the production logistics and ensure optimum protection of the components.

“With this project, the production logistics in the automotive industry have reached a new level,” Feurer continues. “The basis of this is the particularly intense collaboration. One of our employees is on the customer’s site and takes over the material flow control and planning. This means that we not only adapt our load carriers with the highest levels of precision to the components in order to package and transport these as efficiently as possible. We also ensure that the planning and control are carried out on time for all load carriers.”

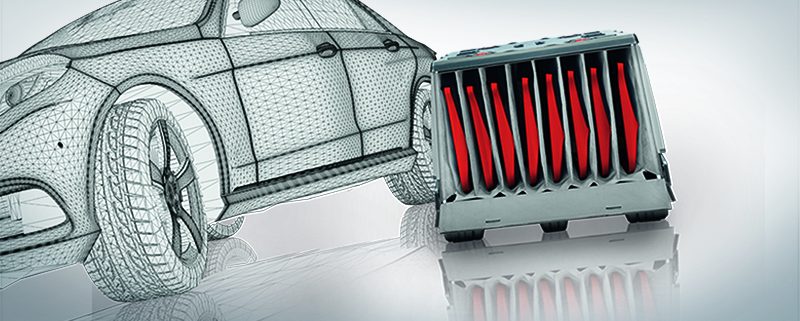

The complex structures and highly sensitive surfaces of the components in some cases repeatedly set new challenges for FEURER. These are mastered with our extensive experience in the field of load carriers. Such as with the pedal unit, for example. Due to its altered geometry, the existing packaging solution was too tight: instead of the 45 components previously, only 36 components could now be fitted into the grid box. “But luckily there is FEURER: a new tray version with a complex but ergonomic design places a full 48 components in a grid box,” says Feurer. “This means that we have not only kept down the storage and transport costs, but have even reduced them by 6%.”