ECO Return Box: Cost savings in no time at all

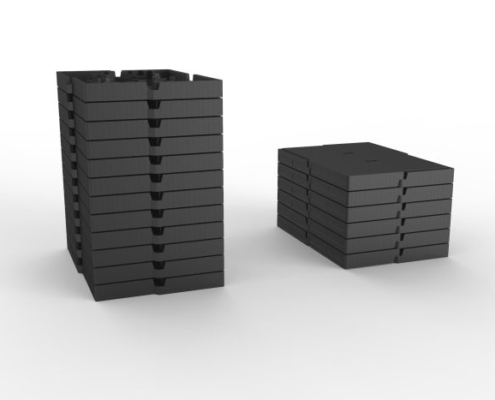

Freight cost-optimised transport of empties is nowadays the focus of the utilisation phase of load carriers. Volume-reducible containers are therefore an advantage. A requirement for this are foldable side walls. Until now, a foamed EPP container could only be reduced in size by using folding or collapsible side panels. The clever design of the ECO Return Box finally enables EPP load carriers to be transported with reduced volume during its empty state.

Volume-reduced-transport of empties

The turning container saves space and transport costs during return transport. In no time at all – in the truest sense of the word. It proves its worth during outward transport due to precise custom holding fits for the components and the easy stacking design of the box itself.

Advantages at a glance:

- Nestable

- Volume reduction in the stack

- Form stability

- For use in Containers or as totes on pallets

- For automotive components such as door seals, trim strips, headlights, etc.

Intelligent solution

The EPP load carriers make themselves suprisingly tiny after emptying. The stack of empties is half the height of the full load.

Advantages at a glance:

- Volume reduction in the stack

- Stable side walls

- Without folding mechanism

- Reduces space requirements by almost 50 percent

- Reduces the transport expense

- Saving costs throughout the entire utilization cycle

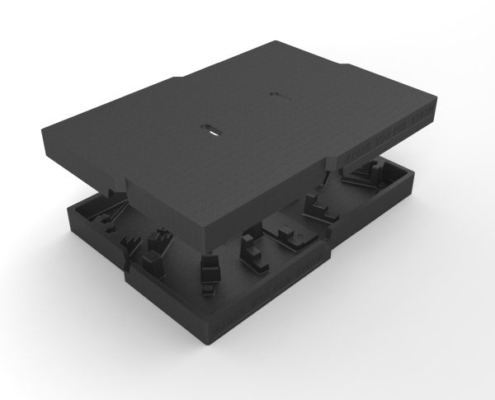

Corners displaced inwards

Precisely shaped holders for the components

Two grip holes for easy handling

Extraordinary design

Two inwardly shifted corners, or eight side walls, enable rotary stacking. When plugged together, the result is again the usual view of stacking containers.

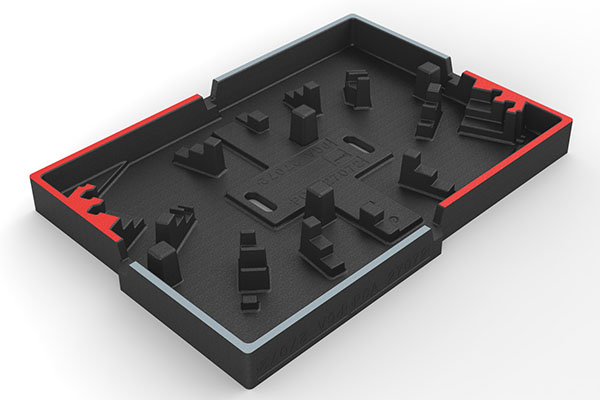

Advantages at a glance:

- With individual mounts adapted to the component

- Optimum packing density adapted to the total weight

- External dimensions adapted to existing grid boxes or pallets

- Solid and stable side walls